News

In Lviv, the Unbroken National Rehabilitation Center has already treated more than 16,000 wounded civilians and soldiers, including 2,000 children. More than 100,000 surgeries have been done. "Everyone is on adrenaline. Everyone is motivated. We are in survival mode. We do it because our friends, our parents, our husbands are on the battlefield", says M aryana Svirchuk from Unbroken . It is estimated that more than 10,000 Ukrainian civilians and 70,000 soldiers have been killed since Russia invaded on February 24, 2022. Nearly 19,000 civilians and 100,000 soldiers were reportedly injured. When the war began, the regional civilian hospital had to quickly change course to meet demand, but the staff had little experience in treating war wounds. In addition, the city's hospital has had to adapt to a very large volume of new patients – thousands of Ukrainians who have fled the fighting in the west to settle in Lviv. ...... For the complete story, please follow this link .

Amid the tragedies of the war in Ukraine , t here are small victories, small incidents of hope that inspire and rally the defenders. One of those moments came on Sunday in Kyiv, when war amputees fitted with prosthetic legs took part in a charity race that made crowds cheer with pride. The race, organized by the Nova Post express delivery company and billed as the “World’s Longest Marathon” – a reference to the 3,359 days that have passed since the war started with Russia’s invasion of Crimea in 2014 – included 15 amputees who were given new limbs in the Unbroken National Rehabilitation Center at St. Panteleimon hospital in Lviv. One of them, Serhii Yevtushenko, walked and ran his one-kilometre event with a prosthesis made from a Canadian-donated 3D printer that was recently installed at Unbroken. “I had no problem with my new Canadian leg,” he told The Globe and Mail after the race. “Morally, this event felt good and I would like to thank Canada.” ...... For the complete story, please follow this link .

For alumnus Jerry Evans , every job is a custom job. “The shape of a person’s limb is as unique as their signature,” he says. “You can’t meet this need with mass production.” After graduating from the University of Toronto with a master's degree in civil engineering, Evans pursued an MBA and had a successful 20-year career in the financial sector. Today, he is the CEO of Nia Technologies Inc., a not-for-profit social enterprise that uses computer-aided design (CAD) software and 3D printers to enhance the fabrication of prosthetic devices around the world. The company collaborates with clinics and hospitals worldwide, including in Canada, Uganda, Tanzania and Cambodia. For full story, please follow link here .

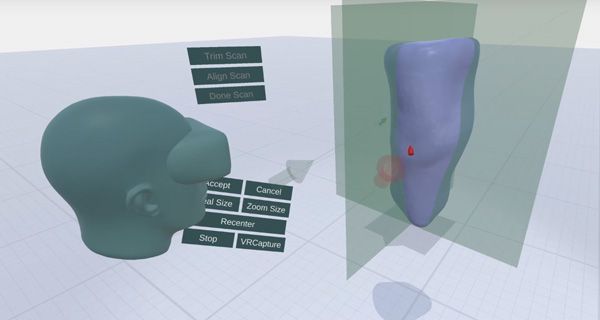

We are proud to be showcased by Stephen Reid in VIVE blog for our work on OrthoVR , a solution that combines virtual reality with 3D software to help clinicians in resource poor setting produce 3D printed prosthetics and orthotics faster. The following is an excerpt of the article. You can read the full story here . Millions of people around the world suffer amputation and disability due to war, accident, and congenital conditions. Yet relatively few of them have access to mobility aids that would allow them to walk, a freedom most people take for granted. Without prosthetic limbs, it can be incredibly difficult to participate in education, work or even social activities, especially in the developing world. Beyond the tremendous impact this has on individuals, there are economic and social costs to families and even communities. With the advent of low-cost 3D printing, the production of suitable prostheses is now possible almost anywhere. Organizations like Canadian non-profit Nia Technologies are helping clinics in low and middle-income countries to manufacture prosthetic and orthotic devices faster than ever before. From digital scanning through design and 3D print production, Nia is helping clinics across the developing world to serve people affected by missing limbs. There’s one problem: the complexity of 3D design. The solution? It might be adding virtual reality to the process. Traditionally, clinicians who work with prosthetic limbs are trained in manual practices, such as plaster casting, sanding and shaping of prostheses. While clinicians can see the benefits of using 3D printing to create materials, often they have difficulty in adapting to the other part of the design process: digital modeling. With 3D printing solutions, clinicians are no longer working with their hands – they are working with a mouse. While some can adapt, for many it’s a difficult process. They’re used to touching, shaping and examining their creations, like so many craftspeople before them. While 3D printing makes the production process faster, ironically the challenge of visual design can make the overall process slower. The solution could be virtual reality: making the design process truly three-dimensional, and putting creativity directly back into the hands of those creating these prostheses. This is exactly what OrthoVR aims to do.

Comprehensive Community Based Rehabilitation in Tanzania (CCBRT) hospital is using 3D printers to make artificial limbs, shortening a process that used to take weeks to just a few hours. Researchers want to see if this technology can be scaled up to meet the needs of the estimated 3.5 million people living with a disability in Tanzania. For VOA, Willy Lowry has the story from Dar es Salaam. Watch VOA’s video here .

Kampala, Uganda – Monday June 13, 2016: CoRSU Rehabilitation Hospital is once again hosting Canadian researchers from Nia Technologies Inc. (Nia) and the University of Toronto to field test 3D PrintAbility technology innovation with orthopaedic clinicians and young people with disabilities (5-25 years). 3D PrintAbility uses 3D scanning, modelling, and printing technologies to design and make custom mobility devices. Originally developed to produce 3D printed transtibial (below-the-knee) prostheses, the product line has expanded to include much-needed Ankle Foot Orthoses (AFOs or braces), devices used to treat club foot, post-injection paralysis, and other common causes of disability among children in Uganda. “We are always looking for innovative ways to improve patient care and increase access to life-changing mobility devices. We are therefore proud that 3D PrintAbility’s first-ever field test was at CoRSU in 2015. It proved that prosthetic socket production time could be cut by as much as 70%, from 5 days with conventional manual methods to 1.5 days with 3D PrintAbility. We are excited to see how the technology and materials have developed since the research team was last in Uganda,” says Moses Kaweesa, an Orthopaedic Technologist at CoRSU. This research is intended to develop innovations that integrate with current practices and increase efficiencies. “Clinical partners are critical to our efforts to develop 3D PrintAbility as a solution that will work in resource-limited settings. Together, we are creating a system that builds on the skills and expertise of orthopaedic clinicians, allowing them to minimize time on manual production and maximize time on decisions about device design, fit, and patient care,” explains Jerry Evans, Nia’s Chief Executive Officer. The collaboration between CoRSU and Nia is aimed at transferring technology in appropriate and sustainable ways that improve access to transformative mobility devices for children with disabilities. Production efficiencies will improve patient care: with less time spent at hospital for patients and caregivers when the device is made (one overnight stay instead of a week); and with improved health and social well-being. In 2016, 3D PrintAbility is being field tested with clinical evaluations in Uganda and other countries. The purpose of the clinical evaluations is to further test: the appropriateness of 3D PrintAbility as a tool for orthopaedic clinicians in resource-limited settings; the biomechanical robustness and safety of 3D printed devices; and the strength, durability, fit, and comfort of the devices to children and youth with disabilities. Nia’s team will be at CoRSU from June 10-17 to launch the start of the clinical evaluation which will run from June-October 2016. About CoRSU CoRSU is a Non-Governmental Organization that was founded in 2006 as a Centre for surgery and rehabilitation for people with disability, with special focus on children for whom we provide free surgery. The hospital specializes in Orthopaedic and Plastic/Reconstructive surgery and has made a tremendous contribution towards improved quality of life for people with disabilities. Additionally, we provide assistive devices, physiotherapy and Community Based Rehabilitation (CBR) to our patients to enhance full recovery. Every year, over 4600 surgical procedures are performed to correct deformities and improve mobility and quality of life. About Nia Technologies Inc. Nia Technologies Inc. is a Canadian non-profit social enterprise that develops and deploys 3D PrintAbility orthopaedic solutions in developing countries. Formed and owned by cbm Canada, Nia is supported by the University of Toronto, Grand Challenges Canada, and other foundations and donors. niatech.org